Important

changes and new features of LabVision 2.10

05.03.2010 HBr

Windows compatibility

- LabVision 2.10 is compatible with Windows XP, Windows Vista and Windows 7

in 32-bit model implementation.

- Using a 64-bit operation system allows to use all components except

of the RI-Editor. The RI-Editor uses a 16-bit programming model and

can therefore not be used directly from LabVision Designer. But

notice, that worksheets that are equipped with embedded RI-Editor

paintings could started in LabVision without any problems.

New features of LabVision 2.10

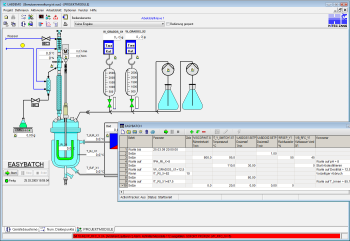

- Table based recipe control with EasyBatch™ and ActionTracker™

Reproducibility and clear

documentation of a test procedure are the requirements to assure

quality and to reduce development times. This can only be

reached in the scope of reasonable expenditure through automation of the

procedure already in the research laboratory. Up to now, only the

text-based language HiText™ or the graphical sequential function

chart HiBatch™ were available for programming. As a new option of

unmatched simplicity, EasyBatch™ is now available. EasyBatch™

enables uncomplicated table-based and and self-documenting programming.

The operation can be conducted on an intuitive basis. EasyBatch™

can also be used in combination with the manual operation mode and

ensures reproducibility in an easy manner. EasyBatch™ is even

simpler to handle as HiText™ and HiBatch™ and is in

particular suited for the programming of processes of simple to medium

complexity. EasyBatch™ is also ideally suited for the control of

fermenters, micro reaction technology plants, and robots. An own table

column is provided for all parameters and values, such as times and

amounts, intended for regulation. The first column contains the order to

be performed. In the simplest case, a program only consists of set and

wait orders. Full flexibility is reached through further commands such

as „Wait until“, „Ramp“, If <Condition>, The table listed

below, depicts the commands in detail. As a special solution, HiText™

programs can be integrated into the procedure, which are controlled by

the Start/Stop/Pause buttons. The command parameters, such as time

intervals, conditions, e.g. "pH > 6,5" or a HiText™

program name are entered into the parameter column. The last column, if

necessary, serves for the entry of comments by the operator for

relevant information which can not be automatically captured.

The user can control

the plant manually with the help of the operating screen. All set

point value modifications are automatically recorded in the table.

All value modifications are added as a line of the table by the

Action Recorder. Consequently, there is a clear and reproducible

description of the actual procedure in table form available at the

end of each process. In other words: A workable program is

automatically established by the operating activities of the

operator without the necessity of any further action. The chain of

activities recorded in table form can now be automatically repeated

without any further effort. It is possible, during the run time or

before the repeated start of the table, to enter intervals, set

points, comments, conditions etc. Usually, before repeated

execution, the table is edited to consolidate the same. Set points

which were modified shortly after another can be summarized in one

line and certain operator-supported tasks such as the reaching of a

certain value (in this case: Wait pH > 7) can be integrated into

the program. If values are modified by the operator during realization,

the table is automatically accordingly adjusted. This ensures that

the procedure is documented and reproducible 100% at any given time.

The LabVision® Project Modules represent the ideal basis for

EasyBatch™. The deployed modules automatically allocate the

EasyBatch™ programs table so that the laboratory work can be

immediately commenced after a project has been established. The

EasyBatch™ Module is therefore the ideal tool to automate

frequently changing applications with minimum expenditure.

Advantages

- Recipe creation without programming knowledge in minimum of time

- Combination of manual and automatic Mode of Operation

- More time for Core Tasks due to a more efficient Mode of

Operation

- Automatic Test Control , also during the Night and Weekends

- Modification of the parameters and procedure also during run

time

- Ideal documentation due to a consistent and complete recording

of measurement values, sequences, events and manual

interventions

- Simplified and safe transfer of the EMSR-Know-How from the lab

to pilot plant and the production stage

- Supports the GLP and GMP suited methods

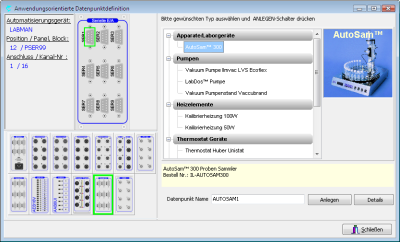

- Application oriented data point definition via simple

mouse click

As

an addition to the normal proven definition masks for creating devices

and data points LabVision now offers a new and very easy to use

"Quick Definition Screen" for commonly used sensors, actuators

and laboratory equipment.

By a simple mouse click to the displayed panel of a LabManager/LabBox,

the user ca select from a predefined list of fully parameterized

devices and sensors, that can be used at the available channels. After

another click LabVision will create a new data point, that is properly

equipped and automatically assigned to the selected hardware channel.

-

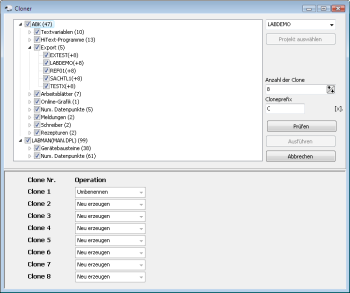

Online data

point cloning tool for multi-reactor plants

The

data point cloner from LabVision version 2.8 was completely been

re-designed. It allows to multiply data points, devices and

relevant project objects like worksheets or HiText programs while

the project application is running. Therefore it possible to develop a

multi-reactor client from a single plant in rapid time. Already cloned

projects can be un-cloned or expanded with more clone layers. The HiText

SL-Multibatch module for parallel syntheses was completely implemented.

-

Fields

for all types of data point

All types of data points (numerical, text and device components) can now

be declared as field. The field index of a single data point is automatically

retained in square brackets. Each single data point of a field

can separately be scaled and parameterized. Thus

a maximum of flexibility is ensured in the project development.

- Expanded and improved libraries

-

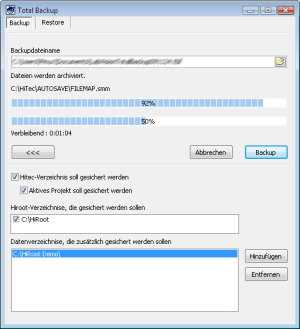

TotalBackup

tool

The

new backup / restore tool allows to backup a complete LabVision installation in a single

file. This image backup can be restored to this or any other

computer. A previous installation of LabVision software is not necessary

when restoring an image backup. TotalBack up can also be used with older

software versions of LabVision (down to 2.5.1.x).

An image file contains the complete LabVision program environment, as

well as all user created projects including their data

bases.

-

PNK-driver

-

New

universal

Multi-PNK driver for the direct

access of

NAMUR or MODBUS devices with the

PC. Serial

ports as

well as

Ethernet ports are supported (via TCP / IP)..

-

Improved

OPCPNK driver with field data point support

-

LabVision Extensions

- The

worksheet designer has many new enhancements. Thus, all used

designer elements can be listed in the object tree according to

their data point assignment. Grouped elements can temporarily be

opened for editing (changing size, moving, property changes). Device

component panels can now show their device icon, which can

also be used as minimizing switch. New Project modules can directly

be loaded from the Designer.

- Multiplotter/Online Chart are now creating user comments with the

name of the creating module. This name can be used to filter in process report. Every plotter/chart instance can set a

filter to show only the comments of its own chart.

- The

handling to set analysis- und delta-t cursor was simplified.

- The

process report has new search and filter functions.

Important

changes and new features of LabVision

Version 2.9

see this document

|